Process analysis technology and instrumentation

PROCESS ANALYSIS SYSTEMS, PROCESS ANALYSIS CABINETS, PROCESSANALYSIS HOUSES/CONTAINERS, SYSTEM INTEGRATION

For your analytical applications we are already at your side during the project planning to realize an optimal system. The engineering can either be done by the customer or be a service of our company.

The required components are either determined by you or in consultation with you. Due to the diversity of our company you save unnecessary interfaces and can always expect best matching and high quality products.

The preparation of the plans in CAD as well as the documentation will be gladly offered by us.

In addition to this, we also offer you the installation and commissioning of associated mechanical components as well as heated sample gas lines from our company.

SYSTEM INSTRUMENTATION

Industrial standard and special products

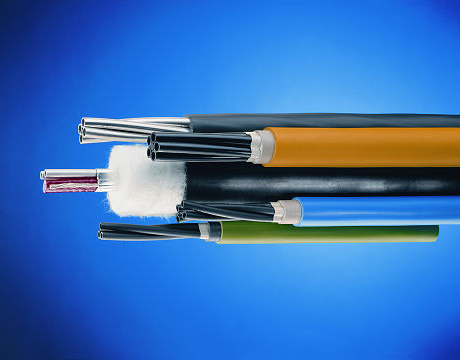

Electrical pipe trace heating

Heated sample gas lines

Associated control and regulation units

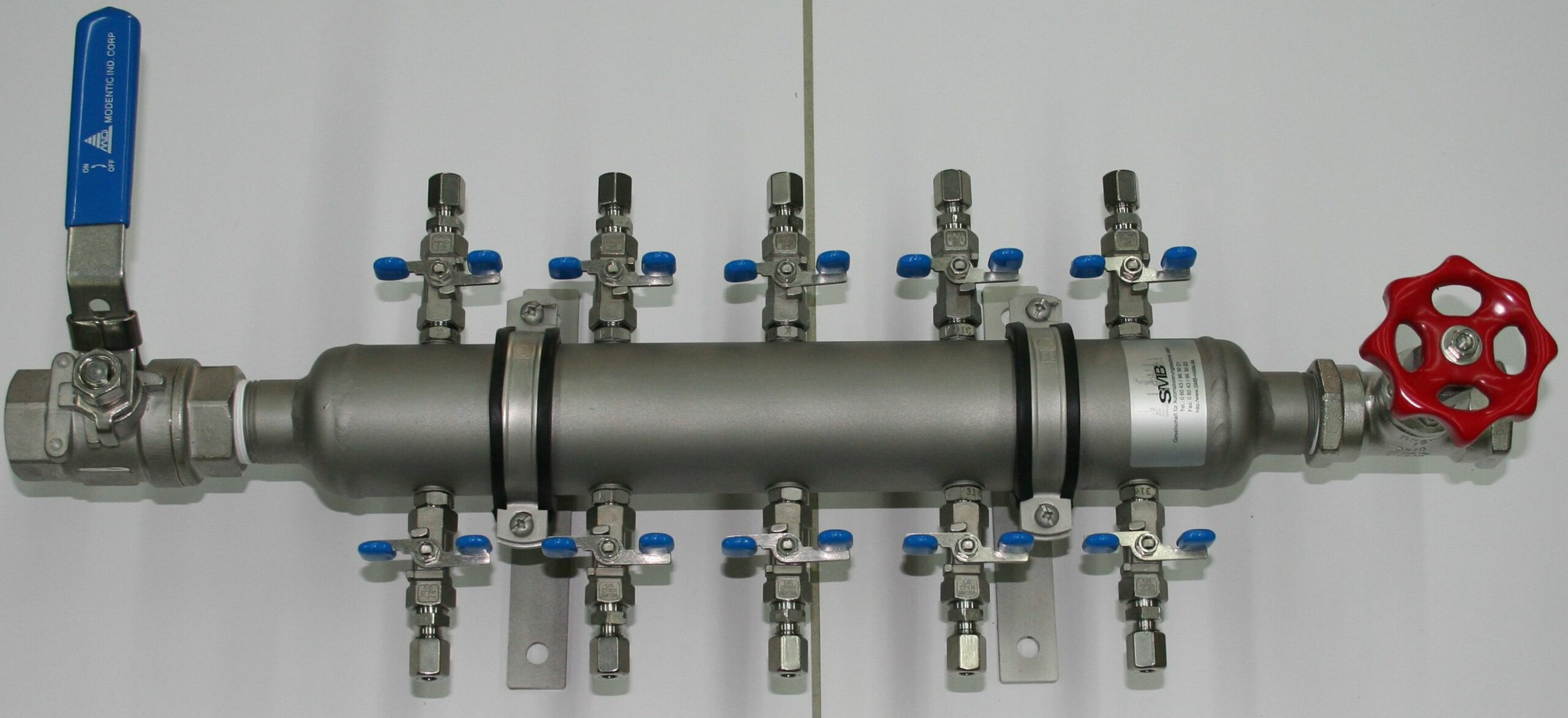

INSTRUMENT AIR DISTRIBUTORS

Manufacture of instrument air distributors for a wide range of requirements.

Production is carried out using the flow drilling method, pressure testing up to 400 bar is possible. Manufacture from corrosion- and media-resistant materials. Post-processing in a blasting process ensures that the highest optical demands are met.

Tests by TÜV Südwest showed that this process meets the highest requirements: bursting could not be achieved up to 409 bar, nor was there any negative structural change. All instrument air manifolds can be supplied with WAZ 3.1 according to EN10204.

ORBITAL WELDING

High-purity welding technology for the highest quality requirements

Welding by certified welders according to EN287-1 with TÜV approval for stainless steel and steel (contract welding on request).

- TIG manual welding

- TIG orbital welding (also for high purity gas applications)

- Electrode welding

- MIG/MAG welding

incl. the tests you need, such as:

- Dye penetrant testing

- Magnetic particle crack testing

- X-ray inspection